Get Quote

News

- What kind of welded wire mesh is a qualified productAnping has many manufacturers that produce welded wire mesh. Some are not a factory at all. Only one worker has one or two machines in it. Their production techniques are generally learned on a temporary basis. After seeing others weaving welded wire mesh, they buy one by themselves. The machine weaves welded wire mesh. They have not been professionally trained at all, but they do not know that there are many technical problems, the control of the mesh, and the detection of the wire diameter. Because there is no training, different problems will be encountered in different periods, resulting in the production of unqualified products, then these products are thrown away is unlikely, still circulating in the market, the use of such welding grid will not meet the requirements A garbage project was born. Here we introduce what kind of welded wire mesh is a qualified welded wire mesh. When we produce welded wire mesh, we have to determine the specifications and wire diameter. We take a 1-inch welded wire mesh as an example, because the welded wire mesh is a very fine thing, welded wire mesh. The diameter can be accurate to 0.01 mm, so there is inevitable error in the wire diameter, but the range of error can not be too large. The general product of 0.02 mm is a qualified welded wire mesh. In the mesh area is also allowed to have errors, but the error of the mesh can not be too large, generally up and down floating about 0.03 mm is qualified.

2020 01/09

- Acceptance welding wire mesh product precautionsFirst, in the time of acceptance of welded wire mesh products, the primary detection is the thickness of the wire, which is the legendary wire diameter. In some of the welded wire mesh manufacturers in Anping, in order to achieve higher profits, sometimes the wire diameter will be somewhat In the normal case, the deviation of the wire diameter does not exceed 0.2mm. Customers can use the micrometer to measure. The second is to weigh the weight of a welded wire mesh product, and then compare the components calculated by the calculation formula to know whether the welded wire mesh product can reach the standard. Third, observe the surface of the welded wire mesh product, observe the name of the welded wire mesh to confirm the type of welded wire mesh, whether it is hot-dip galvanized welded wire mesh or cold-galvanized welded wire mesh, or modified wire welded wire mesh, the surface of the three is similar, Wan It can't be mixed. Fourth, detecting the mesh of the welded wire mesh and measuring whether the mesh can match the request Fifth, check whether the welder of the welded wire mesh can pass the test and see if the solder joint can show signs of welding. Sixth, it is the outer packaging. The normal and regular welded wire mesh manufacturer will stop the outer packaging of the welded wire mesh. Under normal circumstances, the outer packaging will be stopped with the moisture-proof outer wrapping paper. There will be a manufacturer's trademark and another product. Specification label.

2020 01/09

- Welding wire mesh manufacturing processStainless steel welded wire mesh is made of stainless steel wire such as 201, 202, 304, 304, 316, 316l, etc. It is made by fine automatic mechanical technology. The mesh surface is flat, the structure is firm and the whole is strong, even if it is partially cut or Part of the encounter with pressure does not cause a loose scene. Stainless steel welded mesh is one of the stainless steel wire mesh products. Stainless steel welded wire mesh is difficult to cut. Stainless steel is a hard substance with good plasticity and high toughness. However, in the processing time, the cutting is not easy to break and easy to stick, which leads to the cutting and extrusion of stainless steel, which causes the tool to wear moderately (this is due to the wear of the tool, so that the knife face is pitted., causing tiny peeling and gaps; plus the hardness of stainless steel is very high, so choose the right thing according to the material of the stainless steel wire to stop cutting. Use the sander to stop the burr. Stainless steel welded wire mesh is a mechanical welding method with precise welding and high speed. In the welding process, the welding mesh should pay attention to the welding heat. If it is too large, the wire diameter of the welded wire mesh will be broken, which will affect the performance characteristics of the construction. 1. Stop the polished stainless steel and make a safety protection method when welding. 2. Stop grinding the welded stainless steel products again, making the surface generous and elegant. 3. Finally, stop polishing and polishing the stainless steel products.

2020 01/09

- How to choose welded wire meshWelded wire mesh is generally used in the construction field as a building material for construction. For example, the quality of galvanized welded wire mesh is very strict. Nowadays, with the increasing number of welded wire mesh enterprises, galvanized welded wire mesh products are more and more compliant with the requirements of the construction market. It may be uneven. In some applications of welded wire mesh construction mesh, there may be a phenomenon of open welding. In fact, the phenomenon of open welding of welded wire mesh occurs frequently. The reason is nothing more than the problem of warp and weft wire during welding. It may be caused by dirt on the wire, or it may be that the warp and weft wire is not accurate enough in terms of time and welding pressure during the welding process. This technology requires the welding net worker to master after a long period of exploration and practice. . So what kind of galvanized welded wire mesh can be of good quality for customers? Therefore, it is necessary to pay attention to the customers and friends who buy good quality galvanized welded wire mesh. Customers in the purchase of welded wire mesh is generally a problem, the manufacturer must have a sufficient number of meters, the wire diameter is thick enough, the weight should reach the standard, and the mesh should meet the specifications and so on. Of course, these problems naturally require the manufacturer to meet the standard. If even the most basic requirements are not hit, then there are many reputable manufacturers, and such manufacturers will not stay with customers. Whether the customer knows about the welded wire mesh industry, the manufacturer will know the contents of the customer's speech. If the customer speaks, let the manufacturer know that it is not a professional customer of the welded wire mesh. The price given by the manufacturer will not be Really, if the customer said in the process of communication with the manufacturer that it is in the center of the welded wire mesh industry, the manufacturer knows that it is a professional person, and naturally will minimize the price of the welded wire mesh. . So how do you communicate with the manufacturer? This is also a communication skill. First, the communication process should be simple and neat. The customer should think about how to communicate before describing the specifications with the manufacturer, so that the manufacturer can know that the customer is an expert and is a professional who often contacts the welded wire mesh industry. Second, we must focus on the communication process. After the customer talks with the manufacturer about the specifications of the welded wire mesh product, it is necessary to smash the zinc layer of the welded wire mesh or some common loopholes in the welded wire mesh body to ensure the integrity of the welded wire mesh.

2020 01/09

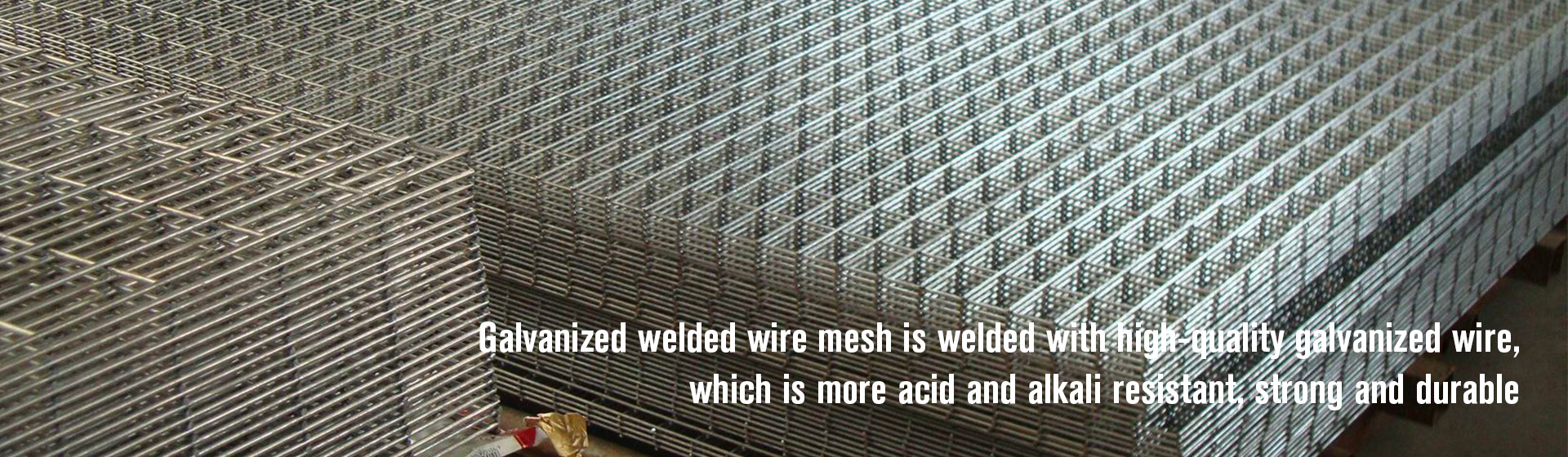

- Galvanized welded wire mesh is widely usedIn the process of industrial production, products such as galvanized welded wire mesh are used in many places. In general construction units, such products are indispensable. So what is the purpose of galvanized welded wire mesh? First of all, the development of welded wire mesh is increasing with the continuous strength of China, and the galvanized welded wire mesh is a new product of the electric welding industry. The product is made of high-quality wire by automated precision welding. After the galvanized welded wire mesh, the mesh surface is flat, the structure is uniform, and the overall performance is very good. Even if it is partially broken or subjected to a large pressure, a little looseness does not occur, so the plating is performed. Zinc welded wire mesh is the strongest anti-corrosion property in the entire iron welded wire mesh, and it is also the most widely used one. In the normal use of the environment, the galvanized welded wire mesh will not only rust, but also produced in a certain British standard, which enhances the anti-corrosion property. The smooth and orderly mesh surface increases the perception and can also play a certain decorative role. . The galvanized welded wire mesh needs to have a certain rust resistance in the production of steel wire after galvanizing welding, and the thickness of the galvanized welded wire mesh produced should not be less than a certain value. At the same time, in the process of transportation, the galvanized welded wire mesh should prevent moisture interference as much as possible, avoid repeated bending, and the protective layer on the surface should also exceed a certain thickness. In these cases, the galvanized welded wire mesh can last for a long time to produce rust resistance and a longer service life. Nowadays, the galvanized welded wire mesh produced by many manufacturers has greatly reduced the production cost through the light mesh structure, which makes many enterprises feel the meaning of good quality and low price.

2020 01/09

- Why does the zinc layer of hot-dip galvanized steel wire fall off?There are many reasons that will cause the zinc layer of the galvanized steel wire to fall off, so what are the specific causes? Let's take a look at the detailed situation together. Hot-dip galvanized steel wire 1.When storing the galvanized steel wire, it is not placed in a dry and ventilated environment, so that it will cause the surface to oxidize. In this way, it will cause the zinc layer of the galvanized steel wire to fall off. It is very important that we pay attention to its storage location. 2.If a silicon compound is mixed in the interior, it will also cause its galvanized layer to fall off when it is used for mixing, so we must pay attention to the mixing of the substances inside. 3. If the furnace itself has a gap, then oxygen will penetrate into it. In this case, it will also cause the phenomenon of detachment. We must also pay attention to ensure that it is within a reasonable time during processing. It is processed, which is an important reason to ensure that it will not fall off.

2020 01/08

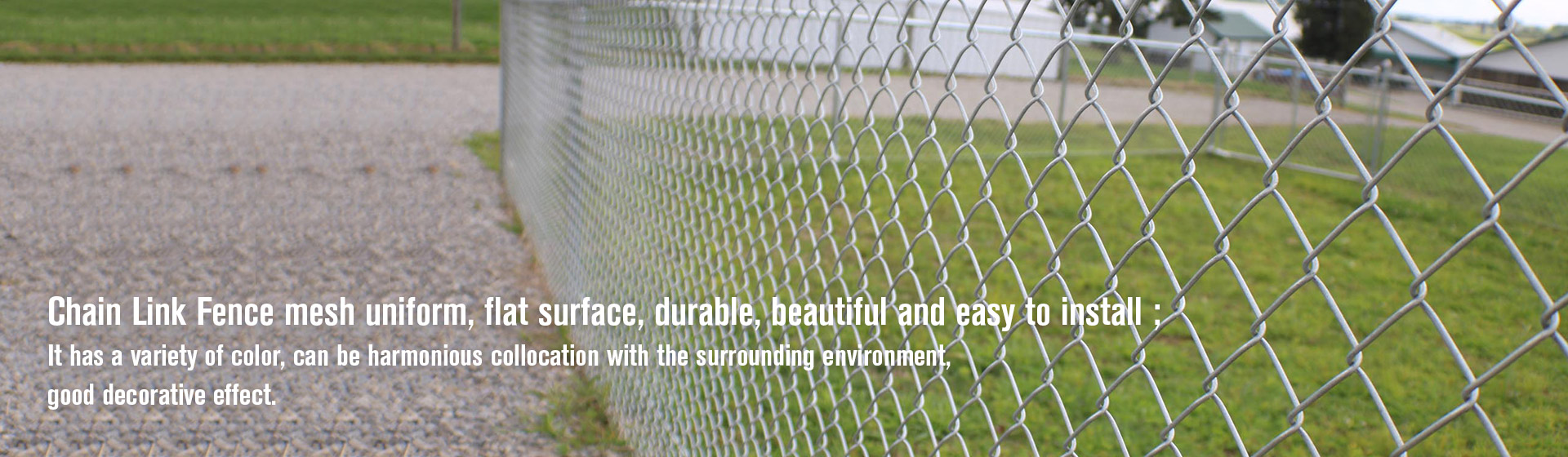

- Compression strength of chain link fencePlastic wire hook chain mesh material: high quality low carbon steel wire (iron wire), stainless steel wire, aluminum alloy wire. Weaving and characteristics: uniform mesh, smooth surface, simple weaving, crocheting, beautiful and elegant; high-quality mesh, wide mesh, thick wire diameter, not easy to corrode, long life and strong practicability. Widely used in highway, railway, highway and other fence network facilities. It is also used for interior decoration, raising chickens, ducks, geese, rabbits and zoo fences. Protective nets for machinery and equipment, conveyor nets for machinery and equipment. Fences in sports venues, protective belts for road green belts. After the wire mesh is made into a box-shaped container, the net box is filled with random stones and the like to become a gabion net. It is also used to protect and support seawalls, hillsides, roads and bridges, reservoirs and other civil engineering. It is a good material for flood control and flood control. Can also be used for handicraft manufacturing. Warehouses, tool room refrigeration, protective reinforcements, marine fishing fences and fences at construction sites, rivers, slopes with fixed soil (rock), residential security, etc. Application example of chain hook tennis court: Application Principles and Practice of Chain Link Fence Animal Farm Example: Tennis court galvanized chain link net system Tennis court that provides protection and safety economically. Tennis Court Galvanized Chain Link Fence For years of maintenance-free and durable protection, the fence of the Galvanized Chain Link Tennis Court System has been selected for decades. Master Harco coats all steel chain link components with zinc proven anti-corrosion technology for more than 200 years. Chain link tennis court systems are easy to install and provide a high level of security. Application: Galvanized tennis court chain link fence system has long been inclined to define property lines, economically attach court facilities and value-added property. The chain link system also allows deductions for easy attachment wind control. Features and Benefits: Tennis court chain link fence systems are commonly used because they are durable and easy to install. The full steel wire component of the master Harvard galvanized chain link tennis court system is hot-dip galvanized and secured to guarantee a 12-year anti-corrosion coating. Tennis court systems used in some installations are made of pressed steel and cast iron for added durability. Principles of chain link fence mountain protection, The air permeability special effect of chain link net is mainly used for large-scale mountain protection to fix rocks. At the same time, green grass seeds are sprayed to achieve the effect of self-solidification in the later stage. It is a perfect combination of greening and protection.

2020 01/08

- The difference between hot galvanized welded wire mesh and cold galvanized welded wire meshThe difference between hot galvanized welded wire mesh and cold galvanized welded wire mesh 1. The galvanizing process is different: the hot-dip galvanized welded wire mesh is galvanized under heating, and the welded wire is immersed in the molten zinc solution for a certain period of time. It is very tight, and other impurities or defects are not easy to be left in the middle. It is similar to the melting of two materials together in the plating area, and the thickness of the galvanized welded wire mesh is also called electrogalvanized welded wire mesh. After pickling, put it into a solution containing zinc salt and connect it to the negative electrode of the electrolytic device; place a zinc plate on the opposite side of the welded wire to connect to the positive electrode of the electrolytic device, turn on the power, and use the current to move from the positive electrode to the negative electrode. A layer of zinc will be deposited on the welding wire. 2. Zinc layer thickness is different: cold galvanized welded wire mesh has uniform coating and very thin thickness; hot galvanized welded wire mesh has thicker coating and uneven thickness. 3. The appearance is different: the appearance of cold galvanized welded wire mesh is smooth, smooth, and bright. The hot-dip galvanized welded wire mesh has some unevenness, the color is dark, and the appearance is not delicate and bright. 4, different corrosion resistance Cold galvanized welded wire mesh because of the thin coating, the corrosion resistance is poor. Hot-dip galvanized welded wire mesh has good corrosion resistance because it has a thick coating and forms an infiltration layer with the base metal. 5. Different prices: The price of hot-dip galvanized welded wire mesh is higher than that of cold-galvanized welded wire mesh.

2020 01/08

- Buy quality welded wire meshWelded wire mesh is also called steel wire mesh. It is most commonly used in exterior wall insulation in the construction industry. When purchasing welded wire mesh, you should buy it carefully. The quality of the welded wire mesh determines the quality and safety of the wall and the safety of the building. With the continuous improvement of the type of welded wire mesh, there are many welded wire meshes on the market. So how to choose the welded wire mesh you need? The following is a brief introduction to the points to be aware of when choosing a welded wire mesh. First, choose welding mesh according to material Specifically include the following 1. Check the thickness of the wire diameter, the size of the mesh, the material, and the number of meters of the welded wire. These points will affect the price of the welded wire. The customer must make a judgment and analysis based on the above points. 2. When viewing the diameter of the welded wire mesh, the error of 0.0 is basically invisible to the naked eye. In the case of the same mesh, you can know the thickness of the wire diameter by looking at the weight of the net. The heavier the net, the higher the price. 3. Check the mesh of the welded mesh. With the development of the mesh, the mesh is getting bigger and bigger, for example: the original 1 / 2-inch welded mesh is 12.7mm, now it is 13.5-15mm. 4. Distinguish welded wire mesh materials: cold galvanized (more exported), hot galvanized (high price, strong anti-corrosion ability), electroplating (bright and smooth). Second, according to the needs of the purchase of welded wire mesh Understanding the use of welded wire mesh can make us better use and save time. 1. Poultry breeding When breeding poultry, the use of welded wire as a fence can save space and is beautiful. Not only can these poultry enjoy good sunshine, but also it is easy for the owner to manage. Attraction fence Now the fences of some tourist attractions are also completed with welded wire mesh, which can not only let people see the beauty in the fence, but also prevent tourists from destroying the beauty. Welded wire mesh is being widely used in various industries.

2020 01/08

- Features of Welded MeshMaterial: low carbon steel wire, galvanized wire Nets with rich colors are widely used in exhibitions, agriculture, farming, flower fences, window fences, and channel fences. Welded mesh grid structure is simple, construction, transportation. Such as machine protective cover, animal enclosure, poultry cage, corrosion resistance, a protective film is formed on the surface of the welded wire mesh, which can effectively isolate the metal wire from the external water or other corrosive substances. Processing methods can be dipping or spraying. Egg baskets and home office food baskets, paper baskets and decoration, electrogalvanized wire, stainless steel wire. Especially for mountainous and sloping fields, it can effectively increase the use time. The plastic spraying process can make the surface of the mesh show different colors, make the mesh achieve beautiful results, have great adaptability to multi-curved zones, uniform mesh and flat surface. The mesh after dipping is usually used in outdoor, field fences, community fences, various isolation nets Welded wire mesh can be made into mesh form. This product is widely used in industry and has strong protection ability: Advantages: Welding is firm. Ordinary welded wire mesh can be used in the construction industry as a Schleser panel and partition net, and is an ideal material for new high-rise buildings.

2020 01/08

- Galvanized welded wire mesh is widely usedIn the process of industrial production, products such as galvanized welded wire mesh are used in many places. In general construction units, such products are indispensable. So what is the purpose of galvanized welded wire mesh? First of all, the development of welded wire mesh is increasing with the continuous strength of China, and the galvanized welded wire mesh is a new product of the electric welding industry. The product is made of high-quality wire by automated precision welding. After the galvanized welded wire mesh, the mesh surface is flat, the structure is uniform, and the overall performance is very good. Even if it is partially broken or subjected to a large pressure, a little looseness does not occur, so the plating is performed. Zinc welded wire mesh is the strongest anti-corrosion property in the entire iron welded wire mesh, and it is also the most widely used one. In the normal use of the environment, the galvanized welded wire mesh will not only rust, but also produced in a certain British standard, which enhances the anti-corrosion property. The smooth and orderly mesh surface increases the perception and can also play a certain decorative role. . The galvanized welded wire mesh needs to have a certain rust resistance in the production of steel wire after galvanizing welding, and the thickness of the galvanized welded wire mesh produced should not be less than a certain value. At the same time, in the process of transportation, the galvanized welded wire mesh should prevent moisture interference as much as possible, avoid repeated bending, and the protective layer on the surface should also exceed a certain thickness. In these cases, the galvanized welded wire mesh can last for a long time to produce rust resistance and a longer service life. Nowadays, the galvanized welded wire mesh produced by many manufacturers has greatly reduced the production cost through the light mesh structure, which makes many enterprises feel the meaning of good quality and low price.

2020 01/02

Email to this supplier